The in vitro gas production technique has been frequently used to assess biological values of feeds based on their pattern of accumulated gas during incubation with rumen fluid under anaerobic conditions. The technique was initially proposed by Menke et al. (1979) to assess digestibility and metabolizable energy content of feeds commonly fed to ruminants. In that system, fermentation of 200 mg of feed was carried out in 150-ml glass syringes containing 10 ml of ruminal fluid and 20 ml of buffer. Theodorou et al. (1994) described a variation of the in vitro gas production technique in which a pressure transducer was used to read and release the accumulated gas pressures from the incubating syringes. This system likely branched from the work of Beaubien et al. (1988). More recently, Pell and Schofield (1993) designed a closed system with 16 50-ml Wheaton flasks, each connected to a sensor. Data are sent to a computer via an analog-to-digital converter (ADC) card for further analysis. More detailed discussion can be found in Schofield (2000).

After data is collected, kinetic parameters that accurately describe the pattern of fermentation can be obtained. It is important that these parameters have biological interpretations, mainly the fractional degradation (or fermentation) rate (proportion of feed matter that disappears per unit of time, usually hours) and extent of digestion (a proportion of the feed matter that has disappeared due to the fermentation, usually within 48 h). Some techniques to fit data to kinetic models were discussed by Mertens (2005), including curve peeling, logarithmic transformation and regression, and non-linear least squares regression. Several models have been described and used to fit in vitro gas production data to nonlinear functions (López et al., 1999).

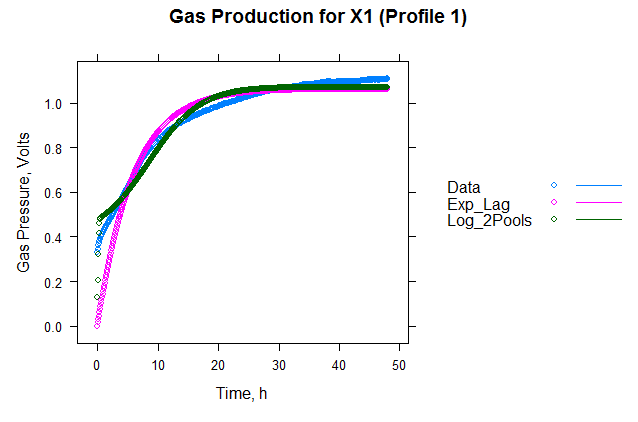

Alfalfa hay gas production (blue) fitted to exponential with discrete lag (pink) and logistic 2 pools (green) models using the GasFit System |

|

|

|

|

|

In order to execute GasFit System, you have to install the following packages: XML and chron. Even though GasFit System will try to install them automatically, you may install them manually. Briefly, after you have installed R, open R, click on menu packages, and then install packages. Select the provider and then select the package one at a time. You have to have internet connection active to download the packages. There is a Visual Basic Script (Install R Packages.VBS) in the GasFit System folder that performs the installation of these packages automatically. |

|||

The current version of the GasFit System is 3.10.8656.16844

|

What is new in GasFit System versions later than 3.0 ? |

![]()

Previous versions can be downloaded from here.

At Texas A&M University (TAMU), we have created some templates to assist in preparing gas production data to be evaluated with the GasFit System. Our gas production system uses Pico Technology (PICOTECH) software. The following templates are provided without any support, some adjustments might be needed depending on the gas production system used.

- The latest Gasfit templates are:

- GasFit Template v. 40 for the Texas A&M University system

- Ankom 2009 Template for the ANKOM system

- The latest script for GasFit (unzip the zip file and copy the .ZZZ file to the My Documents\TAMU\GasFit\Scripts folder) is:

|

A tutorial on how to install and use the GasFit System is available at the Media web page. |

The GasFit System will expires after 5 uses if not registered by the end of the grace period. You can register your copy by submitting the registration number in the Purchase page. Registration codes will not be given out until the cost of registering your copy is paid in full.

Dr. Luis O. Tedeschi |

|